Research, Development and Demonstrations Projects

AMCool

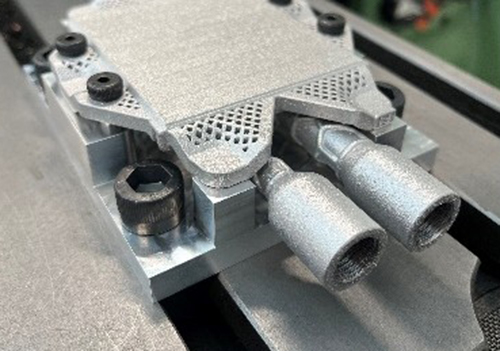

Challenge: Efficient cooling of EV power modules.

Solution: Additive manufacturing of compact micro-heat sinks with optimized heat transfer.

Partners: Danish Technological Institute, Danfoss Drives, Aalborg University

Funding: EUDP – Energy Technology Development and Demonstration Program

AM2pC

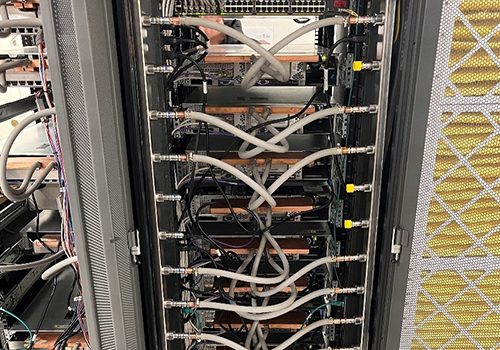

Challenge: High-efficiency cooling in data centers.

Solution: 3D-printed vapor chambers and two-phase cooling structures using copper and aluminum.

Partners: Fraunhofer IWU, Open Engineering, Danish Technological Institute

Funding: M-ERA.NET

LIFE4HeatRecovery

Challenge: Server waste heat utilization.

Solution: Heat recovery from low-grade server cooling, upgraded with heat pumps into district heating.

Impact: CO₂ reduction, lower water use, and community energy reuse.

Partners: Multi-national consortium

Funding: EU LIFE Programme

DfAM Green

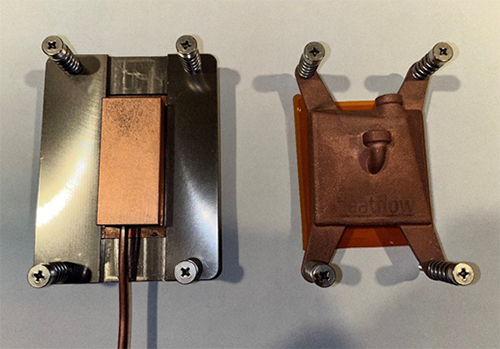

Challenge: Optimize heat extraction for district heating systems.

Solution: Redesign of Heatflow’s evaporator using Design for Additive Manufacturing (DfAM), improving heat transfer and enabling better waste heat reuse.

Partners: Danish Technological Institute, Hexagon, Implement Consulting Group

Funding: Dansk AM Hub

Micro-ORC

Challenge: Generate power from low-temperature industrial waste heat.

Solution: Development of a micro-scale Organic Rankine Cycle system producing electricity from temperatures as low as 85°C.

Partners: FluidTech, Aalborg University, Munk Asfalt, Heatflow ApS

Funding: Energy Cluster Denmark – ETI Program

GREENDC

Challenge: Eliminate active fan cooling in compact electronics.

Solution: Passive, thermosyphon-based cooling system for fanless electronics enclosures.

Impact: Prototype validated as a foundation for greener data center cooling.

Partners: Heatflow ApS, Aalborg University

Funding: Energy Cluster Denmark – ETI Program

Methanol Preheater (MissionBooster)

Challenge: Ensure cold-start capability of e-methanol engines in harsh conditions.

Solution: Development of a self-sustaining methanol preheater using a plasma ignition burner and 3D-printed heat exchanger.

Impact: Validated to start reliably at −20°C; now being adapted for marine use.

Partners: Heatflow ApS, Danish Technological Institute, Alicon, OSK Group

Funding: MissionBooster – Danish Innovation Fund